Whether you are booked for an event as a small business owner, hosting a party at your own home, or just enjoying a quiet night in the backyard with your family – this foldable bar is a perfect addition.

You can easily wheel the bar out when needed, then fold it up and tuck it away when it’s not in use.

Since this is a simple build and easily stored, I’d say it’s a must-have for anyone.

I found my inspiration from the Family Handyman. He has a tutorial video on youtube and free step by step plans on his website!

His build is immaculate but a little outside of my comfort zone when it comes to skill level. If you are looking for a legit quality build, definitely utilize his tutorial!

If you’re like me and need to keep things simple for right now, I’ve got your back.

I utilized plywood for my build 1.) because it’s easy to use and 2.) this bar is actually being utilized by a mobile bartending business (check them out here!) So it’s only outdoors for a few hours at a time during events.

If you plan to keep your bar outdoors full-time, I would encourage you to utilize the same materials as the Family Handyman or perhaps consider exterior grade plywood.

Anyways, let’s get building

Free plans that include dimensions can be found at the Family Handyman’s website here.

Tools I Used:

Materials Needed:

¾” plywood (I used birch)

¼” plywood

1×2’s (I used select pine)

(4) 2” Casters

Here we go:

The first thing I did was cut the front, 2 sides, and countertop out of ¾” plywood using my Kreg track saw. I made the front panel 44″ wide and 41″ tall. Each side panel was 19″ wide and 41″ tall. The countertop was 50″ long x 24″ deep.

Side note: You don’t need a track saw, you can certainly make these cuts using a straight edge and a circular saw. You could even pre-plan and ask the big box store to make the cuts for you. However, if you are regularly doing DIY – I highly recommend this track saw kit. This is how you get more custom & perfect cuts for each of your builds. I was hesitant on purchasing one for a while, but now that I have it – I have zero regrets.

Now that we’ve got the front, 2 sides, and countertop cut, we sand it all down. You can wait to sand everything down at the end but I find it much easier to sand while it’s just a flat sheet vs fully assembled.

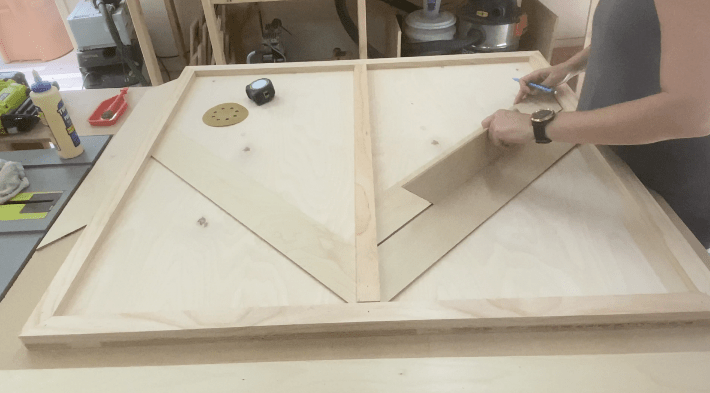

Next, I framed out the front side of the front panel using 1×2’s. I also added a 1×2 going vertically down the center of the front panel to separate the design I wanted to do. I mitered the 1×2’s for a prettier look, added wood glue to the back of the 1×2, and attached to the front panel using 1-1/4” brad nails.

I framed out the front and back sides of the two side panels. I added a 1×2 going horizontally across the back side of each side panel (this is what will hold the interior shelf).

Then I ripped my sheet of ¼” plywood into 4” wide strips using my table saw.

I cut the end of a 4” strip at a 45* miter using my miter saw. I dry fit this onto the front panel and scribed with a pencil mark where I needed to cut off the opposite end. I used a scrap piece of 1/4″ plywood as my spacer between each strip.

I repeated this step until the front panel was covered with the design I had in mind. I adhered the ¼” plywood strips to the front panel using wood glue and 5/8” brad nails.

Next, I framed the edges of my countertop with 1×2’s, but this time I attached the 1×2’s to the side of the ¾” plywood instead of on top like I did with the front + 2 side panels. This gives the illusion that the countertop is thicker than it actually is.

I filled all of my nail holes using wood filler and sanded it down once again using 220 grit sand paper.

This next step was the most intimidating for me: attaching the piano hinges. I’m not even sure why I was so intimidated! But I’m here to tell you, it was a breeze lol

I laid my front panel with the front side facing down. Following the tutorial from the Family Handyman, I used a clamping square to then hold a side panel at 90* to the front panel. I was able to make sure the side panel was flush to the side of the front panel. This ensured everything was a perfect fit before I started drilling.

I pre-drilled each hole inside the hinge and used the small screws that came with the hinge.

After repeating the same process for the other side panel, we had folding sides

woohoo!

Then I quickly found how incredibly heavy this bar was when I tried to stand it up.

This is why I added casters. If you don’t mind hulking it around, casters would not be necessary.

2” casters fit perfectly on the bottom of these panels. I dry fit the castor where I wanted it, then used a pencil to mark where I needed to pre-drill holes. I used 1-1/4” wood screws + washers to attach the castors to the bottom.

I found when I flipped the bar over, and both side panels are folded flat, the bar tipped unless the casters were locked. To avoid difficulty, I just wheel the bar around with the side panels slightly opened up – no tipping problems when you do this.

Now that everything is cut and assembled, I opened the side panels so they were both 90* to the front panel.

I placed the countertop on top and measured to make sure it was sitting exactly centered.

Then I cut some scrap 1×2 pieces and attached them to the bottom of the countertop using wood glue & 1-1/4” brad nails.

I attached one on the inside and one on the outside of each side panel, then one in front of the front panel.

These 1×2 scraps ensure the countertop doesn’t slide around if it’s bumped. Although the casters lock, the 1×2 scraps also keep the side panels at 90* and just make the overall build more stable.

Last, I measured the width and length I needed to cut the interior shelf. Saving this step until the end makes sure you’ll have a perfect fit. I cut the shelf from ¾” plywood using my track saw.

Now you just paint and seal with polyurethane and she is ready to go!

I tested out my new paint sprayer for this project and it was an absolute dream.

I primed using Kilz 2 primer (not needed, I just had a few projects going at once during this time). Then I sprayed on 2 coats of exterior flat white paint and 2 coats of exterior water-based polyurethane (I sprayed 4 coats on the top of the countertop).

I hope this tutorial helps you when you decide to tackle this project for yourself!

You can knock this build out in a day and enjoy snacks/cold drinks on it once you’re finished. 🙂

I’d love to hear how your build goes and see pictures once you finish. Let me know your thoughts in the comments below.

Disclaimer: DIY and working with tools have inherent risks. The projects presented on this website are meant for inspiration only, as the conditions, materials and tools on your own project will vary. Always follow the manufacturer’s instructions provided with your tools and abide by local building codes. Noble Dizzigns will not assume any liability for any damages, losses or injury sustained in the course of your own project.